Introduction

We entered the aluminum truck body market in 2009, after playing a key role in the aluminum recreational trailer business. Prior to our involvement, steel dominated the recreational trailer market. In fact, in 1995, less than 10% of trailers were built from aluminum. Today, aluminum trailers account for more than 40% of all recreational trailers, thanks in large part to the F3 management team who drove this shift by developing superior aluminum trailers that sold at steel prices.

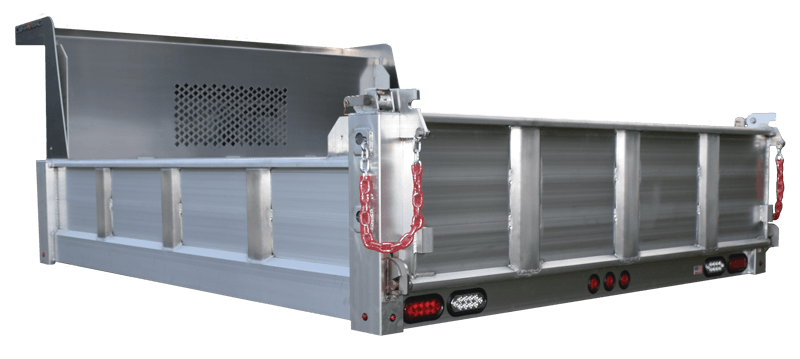

After studying the truck body market, it also became clear that aluminum truck bodies were far superior to their steel counterparts. We studied the players in the aluminum truck body business, and did extensive research to ensure we were – and still are- the best option in this industry.

If you’re still not sure why aluminum truck bodies are superior to their steel counterparts, explore these 10 Advantages to a Lighter Truck Body:

1. “If you can use technology and materials to take weight out of a vehicle, you’ll always end up with the best solution.” (Ford Motor Company)

Per a Forbes.com article, Ford made headlines when they introduced a major shift in the way they manufacture their signature Ford F-150; they used an aluminum truck body instead of a steel one and managed to cut 700 pounds from the truck. Read the entire Forbes.com article here »

According to aluminum.org, “When applied to an optimized automotive body structure, aluminum can provide a weight savings of up to 50 percent compared with the traditional mild steel structure.”

2. Heavier payloads equal less driving miles for your company’s fleet.

2. Heavier payloads equal less driving miles for your company’s fleet.

Because DuraMag aluminum bodies are up to 40% lighter than steel, our customers are able to transport more cargo in fewer trips. Fewer trucks needed means fewer drivers, and less company vehicles to maintain.

3. A lighter truck body means major gas savings.

A lightweight aluminum body translates into fuel savings when you’re at the gas station. Aluminum truck bodies are also more environmentally friendly than steel, as they produce fewer greenhouse gases.

4. Aluminum bodies are easier to repair than steel truck bodies.

This is because aluminum bodies are significantly easier to cut than steel. Not to mention steel bodies and truck beds often require you to scrape the existing, old paint from them before any welding can begin. With the drastic increase in aluminum being used in the auto industry, more and more body shops are equipped to work on aluminum parts, too.

5. Aluminum presents a more polished, superior image for a business.

5. Aluminum presents a more polished, superior image for a business.

A company’s work vehicle is essentially a moving billboard. You wouldn’t let the paint on your storefront chip and peel off because it would look unprofessional to customers as they visited your business. Similarly, it’s important that company vehicles sporting your logo, website and other contact information appear in good working shape and up-to-date. Aluminum truck bodies do not rust over time like steel bodies do. They appear new and polished, year after year when they’re maintained.

6. An aluminum body has a higher resale value.

Steel bodies often last for the span of just one, single company truck, in comparison to an aluminum body which doesn’t deteriorate and can therefore be moved to a second truck when the initial truck wears out. At trade-in time, if you decide to leave your aluminum body on, you’ll get paid for it in addition to the price of the truck itself. On the other hand, rusted steel bodies will generally deduct value from your trade-in.

7. Aluminum has increased corrosion resistance.

Unlike steel, aluminum doesn’t deteriorate overtime. On steel bodies, if the barrier deteriorates between an aluminum skin and the steel sub frame, the body deteriorates fast – Mylar tape to avoid contact between aluminum and steel clearly doesn’t work long term.

8. Aluminum ultimately costs less than half of what steel does.

8. Aluminum ultimately costs less than half of what steel does.

In the past, aluminum has been priced at a premium when compared to steel. At DuraMag, we’re proud to offer competitive pricing on our truck bodies, due to our significant purchasing power and smart design engineering. In addition to our economical upfront costs of aluminum truck bodies, the savings outlined above on fuel, labor, and annual operational costs vs. steel bodies prove there is simply no comparison.

9. Lighter truck bodies help move the industry towards sustainability.

Organizations like the Green Truck Association (GTA) and its Lightweight Technology Council continue to educate and inform members of the work truck industry on equipment and technology improvements to promote commercial vehicle fuel savings. Lighter truck bodies, such as those made out of aluminum, help move the truck market towards friendlier solutions for the environment, while still meeting real-world demands for businesses.

10. Lighter trucks mean less annual maintenance.

This equation is simple: lighter truck bodies mean more payload per haul. This equals less time spent driving, less gas consumed and less wear and tear on company vehicles, annually.